OneSource Environment (BVE3)

Environmental Emissions Evaluator. Chemical Inventory List Management. Hazardous Chemical Reduction.

BVE3 - Environmental Emission Evaluator for Softlines & Footwear

INDUSTRY CHALLENGE

There is an increasing international concern on toxic chemicals being present in the environment. This is largely due to the use of hazardous substances in different manufacturing processes, especially with regards to water bodies and fresh drinking water.

International brands and retailers, under continuous watch of governmental and non-governmental organizations, need to work with supply chain partners to:

• reduce such environmental impacts

• sustain controls over the use of toxic chemicals and

• proactively eliminate these chemicals from the supply chain

Current practices of a once a year water testing and / or screening of materials and manufacturing chemicals may not be sufficient to provide full understanding of the adherence to control toxic substances including the 11 priority chemicals. Brands and retailers are looking for a comprehensive sustainable solution which can help them having a full visibility on their supply chain for continuous improvement.

OUR SOLUTION

To complement our Chemical Discharge Monitoring solution, our BVE3 solution addresses the challenges of how to better understand the hazardous chemical controls of your supply chain. BVE3 additionally enables you to easily identify problem chemicals in support of the elimination of the discharge of hazardous chemicals.

• A supplementary IT tool to facilitate the reduction of environmental impacts

• Systematic mechanism evaluates factories’ discharge potential of priority / hazardous chemicals based on monthly upload of chemical information

• Avoids reliance on one time screening of materials, chemicals and discharge

• Constructs realistic waste water discharge scenarios for the hazardous substances within auxiliary chemicals, dyes, etc…

• Inputs are analyzed with calculated output resulting in the estimated concentration and amount of hazardous substances in water discharge

• Helps identify factories’ potential discharge risk on a continuous basis

• Works in combination with chemicals screening, testing and factory audit

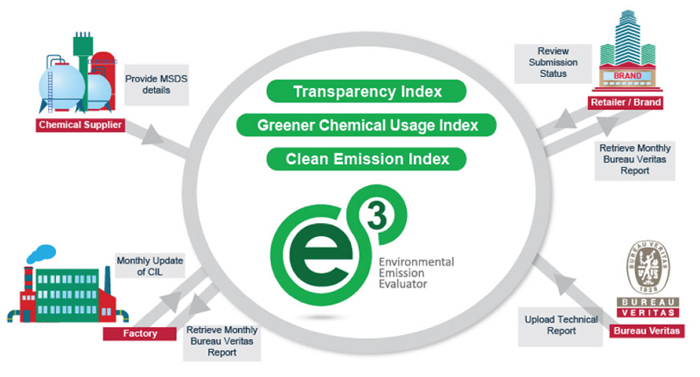

Critically, the number and the amount of hazardous substances in the chemical inventory and discharge create 3 indexes to help measure your supply chain’s chemical management performance and enable optimization:

- Transparency Index. Measurement of the declared chemicals within the chemical inventory as well as the quality of the Material Safety Data Sheets (MSDS).

- Greener Chemical Usage Index. Proportion of declared chemicals that are known to be FREE of hazardous substances.

- Clean Emission Index. The level of hazardous substance free discharge during the manufacturing process.

OUR BVE3 BENEFITS

• Pro-active: A new and sustainable measurement methodology to evaluate supply chain chemical performance comprehensively

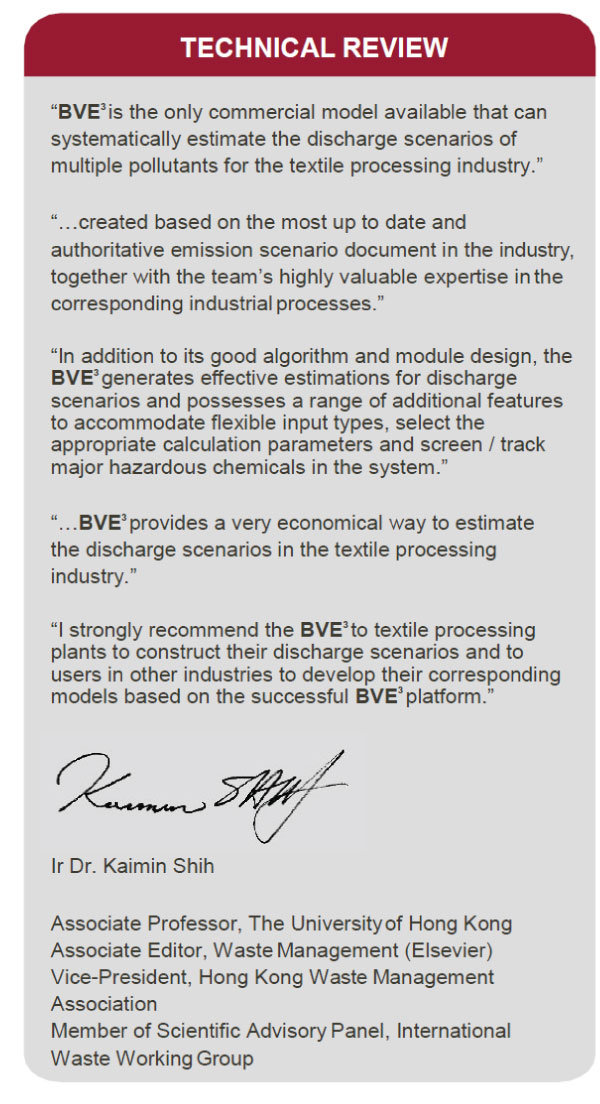

• Effective: Created based on current and authoritative emission scenario documents in the industry

• Independently Verified: Sustainability thought leader independently recognizes platform

• Unique: The first commercial model available that can systematically estimate the discharge scenarios of multiple pollutants for industry with wet processing

• Continuous Improvement Enabler: Provide business intelligence for continuous improvement, enabling optimal chemical supply chain management

• Economically Viable: Reward best in class suppliers who demonstrate hazardous chemical usage improvement with lower levels of intervention and greater volumes

BVE3 UNIQUENESS

Bureau Veritas, a leader in Chemical Discharge Monitoring, has long partnered with different industries to assist in eradicating hazardous chemicals discharge.

We have now launched the world’s first commercially available environmental emission evaluator that systematically estimates the discharge scenarios for various wet processing. Key to BVE3 is the measurement and evaluation of the hazardous chemical discharge to support their eradication by 2020.

BVE3 integrated as part of our supply chain sustainability management solution, together with the discharge testing, auditing and raw material & finished product testing services, resulting in transparency, performance measurement, performance monitoring and continuous improvement.